CHECK LIST FOR JOINING SHIP

Lifeboat Davit Testing

Lifeboat Davit Testing

Traditionally lifeboat davits were tested using sand bags and a crew of strong AB’s. More recently water bags began to be used making the job considerably easier… you simply place the empty bag in the lifeboat, fill it with water, test the davit, then open the bag’s drain valve (do’t foget the lifeboat’s drain plug!).

While not revolutionary Eurodam News, a blog documenting Holland America Line’s newbuild project, gives us the details on shipyard testing of new davits;

For a tender it is:

Maximum number of persons on board: 150

Weight of maximum number of persons: 150 x 75 kg (165.35 pounds) = 11,250 kg (24,802 pounds)

Fully equipped lifeboat: 12,350 kg (27,227 pounds)

Total: 23,600 kg (52,029 pounds)The test is done at 1.1 times the weight they will carry to ensure the complete construction is solidly connected to the side of the ship (the davit arms themselves are tested at the factory at 2.2 times the weight they will ever have to carry — so much stronger).

The yard connected to the lower blocks a big steel box that is filled with water so it totals the desired weight: the weight of the box and the water 23,600 kg (52,029 pounds) multiplied by 1.1 = 25,960 kg (57,232 pounds).

The weight is read by the crane driver, who has a strain gauge in the control cab of the crane. He radios the information down to the people on deck. The crane then slacks its hoisting wire so the davits take the strain. This is called the static test.

For the dynamic test, the manual brake on the winch is lifted and the box is lowered the same way you would lower the lifeboat (or tender, in this case). The lowering speed is then measured, since this needs to be between .75 and 1.30 meters (2.5 and 4.3 feet) per minute. If the boat lowers too slowly or too fast, the centrifugal speed control brake needs adjusting.

Then, after about six seconds the manual brake is thrown back — full force — and the lowering stops. This is rather spectacular, with the box bouncing up and down, and the bulkheads where the sheaves are connected flexing back and forth. Nobody envies the man who has to operate the brake!

ECDIS

ECDIS as an Anti-Grounding Tool

ECDIS can be used as a very effective Anti- Grounding tool when properly set up and used along with appropriate sensors.

The vessels position can be continuously monitored on screen. This facility combined with

On ENC’s alarms can be generated well before the vessel would run into any danger.

In narrow and congested waters the picture by the ECDIS can effectively influence the action taken onboard by the ..... Difference between a vessel aground (or) afloat.

Positive identification of landmarks / navigational aids /buoys/vessels in conjunction with RADAR Overlay to ascertain the quality of sensor input (Position / Echo Sounder / etc.)

Use of true vector, RADAR Overlay & Echo Sounder alarms can effectively help navigate safely under / tidal conditions where vessels are experiencing severe set.

As per IMO performance standards, an ECDIS should have the min.inputs of

- An Electronic Position Fixing System (EPFS)

- To a gyrocompass (HEADING)

- To a speed and distance measuring device (SPEED)

Advantage of ECDIS over paper Chart:

ROTI

INTRODUCTION:

As per SOLAS 2000 Amendment Chapter V Regulation 19.2.9, it is mandatory for ships over 50,000 GRT to have a rate of turn indicator. IMO recommends that large alteration of courses have to be planned along circular tracks with wheel over point marked.

The Rate of Turn Indicator (ROTI) is a device that indicates the instantaneous rate at which the ship is turning. It is fitted on ship as an independent fitment integrated with the steering gear/auto pilot.

CONSTANT RADIUS TURN:

In this method radius Radius is kept constant.

CONSTANT RATE TURN:

In this method ROT (/t) is kept constant.

WHEEL OVER POINT (WOP):

It is the point on initial course at which wheel is put over to initiate the turning of the vessel. It is

obtained by intersection of initial course by wheel over line.

The distance between the WOP and the ship commencing its turn is denoted by F and depends on:

Size of vessel

Loaded/ballast condition

Trim

Type of vessel etc.

BNWAS

VDR

WHAT IS A VDR?

A VDR or voyage data recorder is an instrument installed on a ship to continuously record critical Information related to the operation of a vessel.

It consists of a recording system for a period of at least last 48 hours which is continuously overwritten by the latest data. This recording is recovered and made use of for various purposes, especially for investigation in the events of accidents.

Purpose/benefits of VDR

VDR data can be used for:

1. Accident investigations2. Response Assessment

3. Training support

4. Promotion of best practices

LRIT

PURPOSE OF LRIT:

The main purpose of the LRIT ship position reports is to enable a Contracting Government to obtain ship identity and location information in sufficient time to evaluate the security risk posed by a ship off its coast and to respond, if necessary, to reduce any risks. LRIT has also become an essential component of SAR operations and marine environment protection.

CARRIAGE REQUIREMENT

Ships in international voyages - Passenger ships - Cargo ships over 300 t - Mobile platforms

INFORMATION TRANSMITTED

Identity (Ship’s LRIT Identifier)

Position (Lat/Long)

Date and time (UTC)

UPDATE INTERVAL

Default value 6 hourly

Update interval remotely selectable

Minimum interval 15 min

May be switched off by the Master under certain conditions

THE LRIT SYSTEM CONSISTS OF:

1. The ship borne LRIT information transmitting equipment

2. Communications Service Providers (CSPs)

3. Application Service Providers (ASPs)

4. LRIT Data Centres (DC), including any related Vessel Monitoring System(s) (VMSs)

5. The LRIT Data Distribution Plan (DDP)

6. The International LRIT Data Exchange (IDE), and,

7. LRIT Co-Ordinator

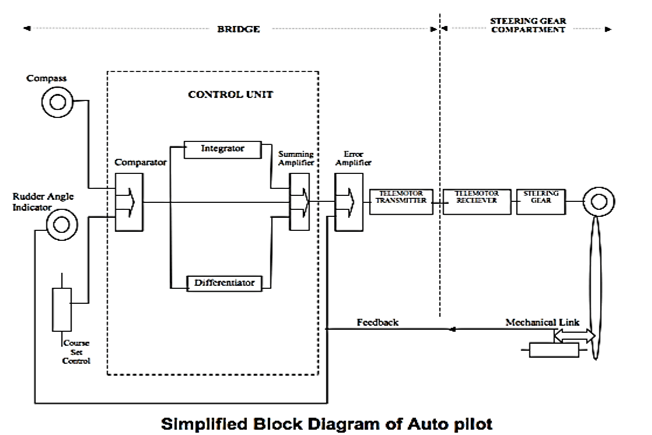

AUTO PILOT

Autopilot is the ship‟s steering controller which automatically manipulates the rudder to decrease the error between the reference heading and actual heading.

Autopilot relieves the helmsman to great extent but definitely autopilot is not a substitute for helmsman.

Autopilot also reduces fuel consumption as the zig-zag course is avoided.

To be used only if a constant influence, like cross wind or beam sea is experienced. If there is a very strong beam wind from starboard side then a permanent 5 degrees starboard helm may be set.

• Rudder:

This setting determines the rudder to be given for each degree of course drifted. Eg. 2 degrees for every 1 degree off course.

• Counter rudder:

Determines the amount of counter rudder to be given once v/l has started swinging towards correct course to stop swing. Both rudder & counter rudder to be set after considering condition of v/l (ballast, loaded, etc.). Eg. Laden condition full ahead, not advisable to go over 10 degrees rudder.

• Weather:

AIS

SOLAS CARRIAGE REQUIREMENT

The carriage of AIS on board ships is governed by SOLAS regulation V/19.2.4. The regulation requires AIS to be fitted aboard all ships of

- 300 gross tonnage and upwards engaged on international voyages,

- cargo ships of 500 gross tonnage and upwards not engaged on international voyages and

- All passenger ships irrespective of size.

- Static information

- Dynamic information

- Voyage related information

RADAR

The term “Radar” is an acronym for Radio Detection and Ranging”.

Principle:

A radio wave is transmitted and received back by the scanner. The time is calculated between transmission and receiving back this wave. The speed of the radio wave is known and thus the receiver unit calculates the distance of the target. After processing, it displays this information on the display screen. The rotating scanner also calculates the bearing of the target and displays on the radar screen.

IMPORTANT CHARACTERISTICS OF A RADAR .

1) VERTICAL BEAMWIDTH (VBW):

IT IS THE VERTICAL ANGLE AT THE SCANNER CONTAINED BETWEEN THE UPPER &THE LOWER EDGES OF THE RADAR SETS BEAM.AS PER THE IMO STANDARDS THE RADAR SET SHOULD FUNCTION IF THE VESSEL IS ROLLING OR PITCHING +_10 DEG WITHOUT DETERIOATION.

MARINE SETS HAVE A VBW OF 15-30 DEG.

2) HORIZONTAL BEAM WIDTH (HBW):

IT IS THE HORIZONTAL ANGLE AT THE SCANNER CONTAINED BETWEEN THE LEADING & THE TRAILING EDGE OF THE RADAR BEAM .IT CAUSES ALL THE TARGETS TO APPEAR LARGER IN AZIMUTH BY AN AMOUNT EQUAL TO HLF THE HBW.

3) PULSE LENGTH:

DUE TO THE PULSE LENGTH THE POINT OF THE PPI APPEARS TO HAVE A RADIAL DEPTH OF HALF PL IN METERS.IT IS THE TIME INTERVAL BETWEEN THE TIME TAKEN BY THE PULSE TO LEAVE 5HE LEADING AND THE TRAILING EGDES.

4) PULSE REPITION FREQUENCY/(PRF):

IT IS THE NUMBER OF PULSES SET OUT THROUGH THE SCANNER IN ONE SECOND. IT ISBETWEEN 500-4000.LONGER RANGES HAVE LOW PRF.SHORTER RANGES NEED HIGH PRF FOR BETTER PICTURE RESOLUTION.

5) WAVELENGTH:

AFTER RADAR ENERGY LEFT THE SCANNER THE PATH ENERGY &TRABEL ARE INFLUENCED BY :1)ATTENUATION, 2)DIFFRACTION.

X BAND: 3CM WAVELENGTH.(9300-9500 MEGS)

S BAND :10 CMS WAVELENGTH.(2900-3100 MEGS)

3CM :GREATER ATTENUATION ,LESS DIFFERENCE ,GOOD FOR SHORT RANGES.

10 CM: LESS ATTENUATION, MORE DIFFERENCE,GOOD FOR LONGER RANGES.

LIMITATIONS OF RADAR SET:

1)RANGE DISCRIMINATION:

IT OIS THE ABILITY OF THE RADAR SET TO CLARLY DISTINGUISH TWO SMALL TARGETS ON THE SAME BEARING AT SLIGHTLY DIFFERENT RANGES.

THE DISTANCE BETWEEN THE TWO TARGETS IS EQUAL TO OR LESS THAN 1/.2 PL.

2)BEARING DISCRIMINATION :IT IS THE ABILITY OF THE RAAR SET TO CLEARLY EXTINGUISH TWO TARGETS OF THE SAME RANGE AND SLIGHTLY DIFFERENT BEARINGS.FACTOR:HBW.

3)MINIMUM RANGE:

A) THE PULSE LENGTH :THE TR CIRCUIT PREVENTS THE TX OF ANY SIGNAL BEFORE RECEIVING IT.HENCE,THE THEOROTICAL MINIMUM RANGE OF DETECTION IS REPEATED BY HALF PL IN MINUTES.

A PL OF 0.2 MICRO WOULD HAVE ARANGE OF 30 MTRS.

B) DEIONISATION DELAY: A SMALL DELAY OCCURS IN THE TR CELL BETWEEN THE COMPLETION OF TX &RECEIVING. A DELAY OF 0.5 MICROSECS.WOULD INCREASE THE MINIMUM RANGE A FURTHER BY 7.5 MTRS.

C)THE VBW +THE HEIGJHT OF THE SCANNER.

4)MAXIMUM RANGE:

A)HEIGTH OF THE SCANNER INCREASES THE SCANNER , THE INCREASE OF RANGE.

B) POWER OF THE SET ,MARINE RADAR SET TRANSMITS AROUUND 25 TO 60 KWTS.

C) WAVELENGTH : 10 CMS HAVE EXTENDED RANGE AS COMPARED TO 3 CMS.

D) PULSE REPETION FREQUENCY:

E) PULSE LENGTH: LONG PULSES ENSURES BETTER MAXIMUM RANGES THAN SHORTER PULSES CAUSE ,LONG PULSES HAVE MORE WAVELENGTH IN THEM.

F) VBW/HBW:THE NARROWER THE BEAM WIDTH THE GREATER THE DIRECTIONAL CONCENTRATION,INCREASES THE RANGE.

5)ANOMALOUS PROPOGATION: SUPER REFRACTION CAUSES AN INCREASE IN MAXIMUM DETECTION RANGE. THIS IS CAUSED DUE TO METEOROLOGICAL FACTORS LIKE TEMPERATURE INVERSION.

RANGE ACCURACY: ACCORDING TO IMO PERFORMANCE STANDARDS THE ERROR IN THE RANGE OF AN OBJECT SHOULD NOT BE MORE THAN 1.5% OF THE MAXIMUM RANGE SCALE IN USE OR 70 MTS WHICHEVER IS THE GREATER.

BEARING ACCURACY: ACCORDING TO THE IMO PERFORMANCE STANDARDS THE OBJECT SHOULD BE MEASURED WITH +_ 1 DEGREE OF ACCURACY.

THE FOLLOWING ARE THE MERITS/DEMERITS OF USING HEADS UP MODE / NORTH UP MODE:

HEADS UP DISPLAY:1) PICTURE SMUDGES IN AZIMUTH DURING ALTERATION OF COURSE.

2) BECAUSE OF SMUDGING ACCURATE BEARINGS CANNOT BE TAKEN AT THAT TIME.

3) PLOTTING TENDS TO BE HIGHLY INACCURATE DURING SEVERE YAWS.

4) ALL BEARINGS ARE RELATIVE.

5) RADAR PICTURE IS HEAD UP WHILE CHART IS NORTH UP.

6) AFTER LARGE ALTERATIONS OF COURSE THE OBSERVER TENDS TO GET DIS- ORIENTED WITH PLOTTING AS ALL TARGETS HAVE SHIFTED.

7) NO INDICATION ON THE SCREEN OF GYRO COURSE STEERED.TEMPORARY WANDERINGS MAY GO UNDETECTED.

NORTH UP DISPLAY:

1) PICTURE DOESN’T SMUDGE IN AZIMUTH AND BEARINGS CAN BE TAKEN ACCURATELY.

2) PLOTTING IS QUITE ACCURATE EVEN DURING HEAVY YAWS.

3) ALL BEARINGS ARE TRUE.

4) CHART AND PPI. BEING NORTH UP IT IS EASIER TO RELATE.

5) THERE IS NO DISORIENTATION DUE TO ATERATION OF COURSE.

Advantages of RADAR:

Radar Performance test checks the transmission and receiving power of the radar. For example if the transmission power of the radar is not enough, radar may not be able to paint some of the target at all. Or radar may only be able to paint the targets with very less sensitivity (faint echoes).

What are controls of RADAR?1. Brilliance

2. Focus

3. Gain

4. Tuning

5. Anti sea clutter

6. Anti rain clutter

EM Log

Principles of Electromagnetic Speed Log:-

- The electromagnetic log is based is upon the induction law, which states that if a conductor moves across a magnetic field, an electro motive force (e.m.f.) is set up in the conductor.

- Alternatively, the e.m.f. will also be induced if the conductor remains stationary and the magnetic field is moved with respect to it.

- The induced e.m.f. is directly proportional to the velocity.

- Velocity when integrated with time gives distance

- The induced e.m.f. "E" is given by the following:

E = F X L X V

- Where F = magnetic field

- L = the length of the conductor

- V = the velocity of the conductor through the magnetic field.

- No moving parts

- Less affected by sea growth than Pit sword

- Salinity and temperature of water affect calibration.

- Measurements affected by boundary layer, (water speed slowed down close to the hull by friction).

- Provides boat/ship speed relative to water not ground. Current affects accuracy.

Doppler log

Principle:

Whenever there is a relative movement between a transmitting source and a receiver, there will be a ‘Doppler shift’ in the frequency received. This shift is termed as Doppler effect.

fr= ft (c+v)/(c-v)

Where

fr = Received Frequency

ft = Transmitted frequency

c =Velocity of sound in Sea Water (1500m/sec)

v = Velocity of the vessel

• Higher the sound frequency, smaller the transducer, narrower the beam and higher the accuracy.

• The beam bounces back from the sea bottom.

• The frequency of the bottom echo will be higher when the ship is moving ahead or lower if she is moving astern.

• The Doppler equation is solved to obtain ship’s speed.

• When signal is bounced off the sea bed, (called Bottom Track), the speed displayed the “Speed over the ground (SOG)”

Echo sounder

Basic Principle

.png)

.png)

.png)

ship construction for oral exam

ship construction

Definitions and Ship’s Dimensions

The structural body of a ship including shell plating, framing, decks and bulkheads.

Afterbody :

That portion of a ship’s hull abaft midships.

Forebody:

That portion of a ship’s hull forward midships.

Bow :

The forward of the ship

Stern :

The after end of the ship

Port :

The left side of the ship when looking forward

Starboard :

The right side of the ship when looking forward

Amidships:

point midway between the after and forward perpendiculars

Length Overall (L.O.A.):

Length of the vessel taken over all extremities.

Base line:

A horizontal line drawn at the top of the keel plate. All vertical moulded dimensions are measured relative to this line

Moulded beam:

Measured at the midship section is the maximum moulded breadth of the ship

Moulded Draft/ Draught:

The distance from the bottom of the keel to the waterline. The load draft is the maximum draft to which a vessel may be loaded

Moulded Depth:

Measured from the base line to the heel of the upper deck beam at the ship’s side amidships.

Sheer:

Curvature of decks in the longitudinal direction. Measured as the height of deck at side at any point above the height of deck at side amidships

Camber / Round of Beam:

Curvature of decks in the transverse direction. Measured as the height of deck above the height of deck at side

Rise of floor / Deadrise:

The rise of the bottom shell plating line above the base line. This rise is measured at the line of moulded beam

Half siding of keel:

The horizontal flat portion of the bottom shell measured to port or starboard of the ship’s longitudinal centre line. This is useful dimension to know when dry-docking.

Tumble home:

The inward curvature of the side shell above the summer load line.

Freeboard:

The vertical distance measured from the waterline to the top of the deck plating at the side of the deck amidships. Normally exposed to weather and sea.

Flare:

The outward curvature of the side shell above the waterline. It promotes dryness and is therefore associated with the fore end of ship

Extreme Beam:

The maximum beam taken over all extremities.

Extreme Draft:

Taken from the lowest point of keel to the summer load line. Draft marks represent extreme drafts.

Extreme Depth:

Depth of vessel at ship’s side from upper deck to lowest point of keel.

Half Breadth:

Since a ship’s hull is symmetrical about the longitudinal centre line, often only the half beam or half breadth at any section is given.

SCANTLING

The dimensions of the structural items of a ship, e.g. frames, girders, plating , etc.

Composed of separate parts, non-continuous

CENTER OF FLOATATION

It is the center of the waterplane area and is the axis about which a ship changes trim.

It is the center of the underwater volume of the ship where the force of buoyancy acts.

It is the point at which the whole weight of the object may be regarded as acting. If the object is suspended from this point, it will remain balanced and not tilt.

- This is often referred to when the size of the vessel is discussed, and the gross tonnage is quoted from Lloyd’s register.

- Tonnage is a measure of the enclosed internal volume of the vessel, 100 cubic feet representing one ton

- Its normally divided into categories as follow:

- DISPLACEMENT TONNAGE

- A ship’s displacement is the sum of the ship’s actual weight (lightweight) and it’s contents (deadweight).

- The metric unit of measurement is 1 tonne (= 1000 Kg).

- The displacement represents the amount of water displaced by the ship expressed in tonnes.

- The weight of water displaced therefore equals the weight of the ship

It is the mass required to increase the mean draught by 1 centimetre.

The weight of the ship and its content, measured in tonne. The value will vary according to the ship’s draught.

It is a scale diagram indicating the deadweight of the ship at various draughts.

It is devised to show the relationship between the form of the ship and the dimension of the ship.

- The lightweight is the weight of the ship as built (hull, machinery) including boiler water, lubricating oil and the cooling water system.

- Lightweight like displacement is expressed in units of tones.

- It assumes importance in a commercial sense only when considering the value of the vessel which is to be broken up for scrape.

- Deadweight is the weight of the cargo which a ship carries plus weights of fuel, stores, water ballast, fresh water, crew and passengers and baggage.

- It is the difference between the loaded ship displacement and the lightweight.

- Measurement of total internal volume of a vessel and includes all under deck tonnage and all enclosed spaces above tonnage deck.

- 100 cubic feet of space being considered as 1 ton

- Ship measurement derived from gross tonnage by deducting spaces allowed for crew and propelling power.

- 100 cubic feet of space being reckoned as 1 ton

LOAD LINE

- consists of a ring 300 mm in outside diameter and 25 mm thick which is

- intersected by a horizontal line 450 mm in length and 25 mm thick, the upper edgeof which passes

- through the centre of the ring. The centre of the ring is placed amidships and at a distance equal to the assigned summer freeboard measured vertically below theupper edge of the deck line.

- The outboard strake of the inner bottom.

- Knuckle down to the shell by means of Margin Plate at angle of 45°to tank top, meeting the shell almost at right angle.

- It can form a bilge space.

Keel plate:

- The first type, used from wood to iron ship building.

- Do not provide sufficient strength for larger ship.

- No direct connection between the keel and floor.

- A keel of welded ship. The centre girder is attached to the keel and inner bottom plating by continuous welds.

- Keel plate width is about 1 to 2 meter

- It must be full thickness, for 3/5 of length amidship and then thickness may reduce towards the ends of ship.

- An internal passage of watertight construction, running same distance along the length of ship, often from fore peak to forward machinery space bulkhead.

- It is to carry pipeworks, and entrance is at forward machinery space bulkhead through a watertight manhole.

Bulkhead

- Constructed to prevent passage of flame for 1 hour standard fire test at 927°C

- It must be insulated so that the unexposed sides will not rise more than 139°C above the original temperature within the time, as follows:

- Constructed to prevent passage of flame for ½ hour standard fire test

- It must be insulated so that the unexposed sides will not rise more than 139°C above the original temperature within the time, as follows.

- They are constructed of non-combustible material.

- The exposure of a material specimen in a test furnace, to a particular temperature for a certain period of time.

- Foremost major watertight bulkhead, which extends from bottom to main deck(upper deck).

- It is at a distance of L/20 from forward perpendicular.

- Used on transverse bulkhead, thus improves transverse strength.

- Any bulkhead, which does not form, part of a tank or part of a watertight subdivision of a ship, may be non-watertight.

- A perforated bulkhead fitted into a cargo tank or deep tank, to reduce sloshing or movement of liquid through the tank.

- Provided to enclose the stern tube in watertight compartment.

- Aft peak bulkhead needs only to extend to first deck above load water line.

- Plating must be doubled to resist vibration around stern tube.

- One collision bulkhead.

- An after peak bulkhead.

- One bulkhead at each end of machinery space.

- Total no: of bulkheads depends upon the ship and position of machinery space

- To increase transverse strength of ship, particularly against racking

- To divide the ship into watertight compartments.

- To give protection against fire.

- To prevent undue distortion of side shell.

- To restrict volume of water, which may enter the ship, if shell plating is damaged.

- Collision bulkhead must extend from bottom to upper deck.

- Aft peak bulkhead needs only extend to first deck above load water line.

- All others must extend to uppermost continuous deck.

- Plating usually fitted vertically, and thickness gradually increases from the top downward.

- Stiffeners are fitted at 750mm apart, but collision bulkhead and deep tanks have 600mm spacing.

- In the events of collision and grounding, standard of subdivision has to give good chance, that the ship remains afloat under such emergencies.

- Longitudinal Bulkheads are avoided, as far as possible, as they might cause dangerous angles of heel, in the event of flooding of large compartment through damage.

- Transverse Bulkheads are reliable in this case, and Classification Society requires a watertight Collision Bulkhead within reasonable distance from forward.

- If the ship is supposed to have wave trough amidships, there will be excess weight amidships and excess buoyancy at the ends, hence the ship will be (Assuming wave length = length of ship)

- If the ship is supposed to have wave crest amidships, there will be excess weightat the ends, and excess buoyancy amidships; hence the ship will be

- By “Trochoidal Theory”, wave height from trough to crest is 1/20 of the wave length, therefore maximum shearing force usually occurs at about L/20 of ship from each end.

- For this reason, Collision Bulkhead is located at L/20 of the ship, so that it is not so far forward, as to be damaged on impact. Neither should it be too far aft, so that the compartment flooded forward causes excessive trim by bow.

- As wave passes along the ship, they cause water pressure fluctuation, which tends to create in and out movement of the shell plating, especially at forward end.

- This in and out movement is called panting.

- Resisting structures against panting are beams, brackets, stringer plates, etc.

- When a ship rolls, there is a tendency for the ship to distort transversely.

- This is known as racking.

- Resisting structures are beam knee, tank side bracket, and especially transverse

- When ship is heaving and pitching, the fore end emerges from water and re-enter with a slamming effect.

- It is called pounding.

- Resisting structure: extra stiffening at the fore end.

- When buoyancy amidships exceeds the weight due to loading, or when the wave crest is amidships, the ship will hog.

- When the weight amidships exceeds the buoyancy, or when the wave trough is amidships the ship will sag.

1) For light 2) For ventilation 3) For escape for emergency.

- Transverse section of a ship is subjected to transverse stresses, i.e. static pressure due to surrounding water, as well as internal loading due to weight of structure, cargo, etc.

- Structures or parts, that resist transverse stresses:

- Transverse bulkhead

- Floors in double bottom

- Brackets between deck beams and side frame

- Brackets between side frame and tank top plating

- Margin plates

- Pillars in holds and tween deck.

- Heavy concentrated loads like engine, boiler.

- Deck cargo such as timber.

- Hull vibration.

- Ship, resting on blocks in dry dock.

- Caused by the motion of the ship itself

- A ship among waves has three linear motions:

- Vertical movement: heaving

- Horizontal transverse movement: swaying

- Fore and aft movement: surging And

- three rotational motions:

- Rolling about longitudinal axis

- Pitching about transverse axis

- Yawing about vertical axis.

- A ship among waves has three linear motions:

- Vertical movement: heaving

- Horizontal transverse movement: swaying

- Fore and aft movement: surging AND

- three rotational motions:

- Rolling about longitudinal axis

- Pitching about transverse axis

- Yawing about vertical axis.

- When ship is carrying timber, the deck cargo gives additional buoyancy and a greater degree of protection against the sea.

- The ship has smaller freeboard than normal (type-B) vessel.

- It is a bulb shaped underwater bow.

- Reduce wave making resistance, and pitching motion of the ship

- Increase buoyancy forward, and hence reduce pitching of the ship

- Outer plating of bulbous bow is thicker than normal shell plating, to resist high water pressure and possible damage cause by anchor and cables.

- Due to reduction in wave making resistance, it can reduce SFOC under full speed and loaded condition.

- Lateral Bow Thrusters are particularly useful, for manoeuvring in confined water at low speed.

- For large vessel, used at channel crossing, and docking.

- For research vessels and drilling platform, etc. very accurate positioning

- Bow Thruster consists of: (As a Rule)

- A controllable pitch or reversible impeller, in athwartship watertight tunnels.

- Bridge controlled and driven by

- Thrust provided is a low thrust, about 16 tons.

- Greatest thrust is obtained, when ship speed is zero.

- Less effective, when ship gets underway.

- Athwartship tunnels appreciably increases hull resistance.

- Close the tunnels at either end, when not in use, by butterfly valve or hydraulic valve.

- A narrow void space between two bulkheads or floors that prevents leakage between the adjoining compartments.

- In tankers, between cargo tanks: In ER, between DB LO tank (sump tank) and adjacent tanks. Maximum width = 760 mm.

- The double bottom consists of outer shell and inner skin, 1m and 1.5 m above thekeel and internally supported by

- Double bottom space is subdivided longitudinally and transversely, into large tank, by means of watertight structures. Its functions are:

- Protection of shell in the events of damage to bottom shell.

- Tank top being continuous increases the longitudinal strength.

- To act as platform for cargo and machinery.

- Can be used for storage of fuel, fresh water, ballast, and for correcting list, trimand draught.

- Diminish oil pollution, in the event of collision.

- To carry water ballast or liquid cargo.

- Protection of shell in the events of damage to side shell.

- To locate oil cargo tank

- To correct list of the ship.

- When ship is underway in light condition, it is necessary to carry certain amount of water ballast.

- If DB tanks alone are used for this purpose, the ship might be unduly “stiff”.

- So it becomes a practice to arrange one of the lower holds, so that it can be filled with water when necessary.

- This permits a large amount of ballast to be carried without unduly lowering the centre of Gravity of the ship.

- Such a hold is called a Deep Tank.

- This tank is usually designed to carry dry cargo, and in some cases may carryvegetable oil or oil fuel as cargo.

- If the tank extends full breadth of the ship, a middle line bulkhead, called Wash Plate must be fitted to reduce free surface effect.

- Strength of Deep Tank structure is greater than that required for dry cargo hold bulkhead.

- Vertical distance from water load line, up to the main deck [freeboard deck], measured at the shipside amidships.

- Main deck is the highest deck that is water sealed. Water falling on upper decksmay run down companion ways, but it cannot go any further down into the ship than the main deck.

- Freeboard has considerable influence on seaworthiness of the ship. The greater the freeboard, the larger is the above water volume of the ship and this providesreserved buoyancy, assisting the ship to remain afloat in the event of damage.

- Watertight volume of a ship above the water line is called the reserved buoyancy.

- It can be defined as the buoyancy, a ship can call upon, to meet losses of buoyancy in case of damage to main hull. [Water plane area, multiplied byfreeboard.]

- To meet loss of buoyancy, in case of hull damage.

- To provide sufficiency of freeboard, to make the vessel seaworthy.

- is structurally adequate for its intended voyages,

- has adequate stability for its intended voyages,

- has a hull that is essentially watertight from keel to freeboard deck, and watertight above these decks,

- has a working platform that is high enough from water surface, to allow safe movement on exposed deck, in the heavy seas,

- has enough reserved buoyancy above the water line, so that vessel will not be in danger of foundering and plunging when in heavy seas.

- Tonnage is a measure of cubic capacity, where one ton represents 100 ft³ or 2.83 m³. It is a measure of the ship’s internal capacity.

- Gross tonnage is the total of the Underdeck tonnage & the tonnage of the following spaces:

- Any Tweendeck space , between second and upper deck.

- Any excess of hatchways over ½ % of vessel’s Gross Tonnage.

- Any permanently closed-in spaces, on or above the upper deck.

- Any engine light and air space on or above upper deck, at shipowner’s option and with Surveyor’s approval.

- Certain closed-in spaces, on or above the upper deck are not included in gross tonnage, and these are known as Exempted Spaces.

- Dry cargo space.

- Space fitted with machinery or condensers.

- Wheelhouse, chartroom and radio room.

- Galley and bakery.

- Washing and sanitary spaces in crew accommodation.

- Light and air spaces.

- Water ballast tanks not appropriated for any other use.

- It is obtained by making “deductions” from the Gross Tonnage.

- Principal “Deducted Space”, which already have been included in Gross Tonnageare:

- Master’s and crew accommodation.

- Chain lockers and space for working anchor and steering gear.

- Propelling Power Allowance.

- Ballast tank, capacity ≯ 90%.

- Port and Harbour dues are assessed on Net Tonnage.

- To determine port and canal dues.

- To determine Safety Equipment.

- To measure the size of fleet.

- If machinery space tonnage is between 13% and 20% of gross tonnage, PPA is 32% of gross tonnage.

- If machinery space tonnage is less than 13% of gross tonnage, PPA is the amount expressed as a proportion of 32% of gross tonnage.

- If machinery space tonnage is more than 20% of gross tonnage, PPA is 1.75 times the machinery space tonnage.

- There is a maximum deduction for propelling power of 55% of gross tonnage, remaining after all other deductions have been made.

- To check the water tightness of hatch covers and watertight doors :

- By using water jet pressure of 2 kg/cm² and a distance of 5 m, and jet diameter ½”.

- If hose test cannot carried out, chalk test can be done.

3. Open the cover or door, and check whether the chalk painted is cut off or not.

Popular topics

-

Passage planning - [For 2nd mate examination purpose only]. Example of Decent passage planning: 👇 Note: Make the plan intend to safe naviga...

-

👍Thumb rule for ship construction diagram: Different books show a different diagram for the same type of ship, so understand the structural...

-

Please read the below definitions before proceeding to understand the flammability diagram. Definition: LEL (Lower Explosive Limit) / LFL (L...

-

Stowage of IMDG cargo Stowage means proper placement of cargo onboard a ship in order to ensure safety and Environment protection. Stowage ...

-

Work and rest hours requirement: As per MLC 2006: Working hours not more than 14 h in any 24 h period, 72 h in any 7 day period or Hours of...

-

Ship Construction Definitions and Drawings: The below definitions are very important and need to know thoroughly. Pls, refer the diagram whi...

-

SHIP STRESSES What is Stress and Strain ? Stress is a load or force acting per unit area ( in kg/mm 2 ). They are maily three types – ...

-

"Condemn" means disapproval, unacceptable. A wire rope should be inspected before use to detect any of the above conditions so th...

-

W hat is BRM? Bridge resource management [BRM] was adopted in the 1990’s by the maritime industry as a safety and error management tool. BRM...

-

"Marine Anemometer" The Marine Anemometer is a weather instrument used to measure wind speed and wind direction. The term anemomet...